Webinar Recap

Recently, LeanDNA had the opportunity to host a discussion of the new shortage economy and more involving experienced manufacturing leaders from Chamberlain Group, HNI Corporation, and PSG Dover.

The three main learning objectives covered in the Building Supply Chain Resilience Webinar included:

- Shortages and issues discrete manufacturers face

- The role technology plays in addressing these challenges

- How to utilize modernized planning and optimization tools for actionable insights

This blog serves as a resource to summarize the key takeaways from the conversation, you can also download the full webinar video for additional details on the topics discussed.

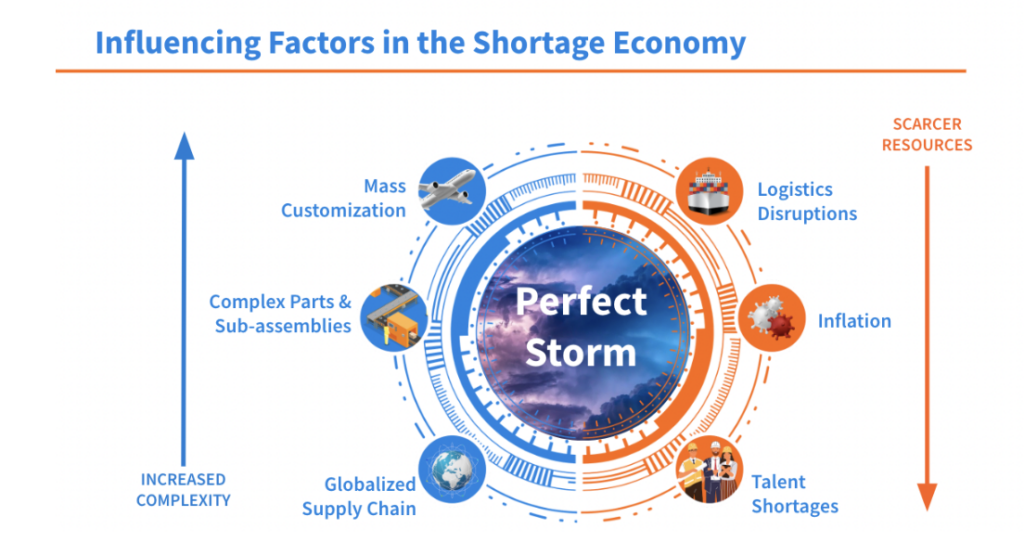

Manufacturers Face a New Set of Challenges from the Impacts of the Shortage Economy

The Great Supply Chain Disruption

With the ongoing effects of the shortage economy, surveys are showing that 83% of the supply chain feels overwhelmed.

To alleviate cognitive overload, manufacturing leaders are looking for ways to digitally transform their supply chain. However, the issue is 83% of companies find that better decision making is lacking, even after implementing technology. Manufacturers are now finding that the complex technology is more difficult to maintain for long term results.

On the other hand, the traditional processes alone are no longer efficient due to the unforeseen occurrences that have impacted the supply chain.

The most common shortage management stopgaps include:

1. Increasing Safety Stock

Additional inventory eats working capital & further amplifies the strain on suppliers to produce the right materials

2. Expediting Materials

Manufacturers pay high fees to expedite materials to service production priorities and avoid further delays

3. Shortage War Rooms

Without real-time, actionable analytics, the reactive cycle of putting out fires on a daily basis will continue

4. Better Planning

Better planning alone doesn’t help supply chains pivot and adapt faster to changing inputs

5. Homegrown analytics

Stale data analytics aren’t able to produce actionable, fast, and updated insights for better decision making

All of the aforementioned stopgaps are creating silos in supply chain execution that create confusion due to lack of communication, collaboration, and aligned decision making.

The burdens of the supply chain disruption are affecting how planners, buyers, and suppliers co-exist under their previous manual system processes.

The Pain Points of Leading Supply Chain Manufacturers

During the Building Supply Chain Resilience Webinar, it was discovered that even though the companies in the conversation served different industries they all had the same overarching issues.

Supply chain leaders from Chamberlain Group, HNI Corporation, and PSG Dover all expressed their similar pain points of wanting to improve complete on-time shipments, reduce extended lead time, optimize inventory, and better supply chain management.

Manufacturing Supply Chain Management is Pivoting to Adapt as Ongoing Challenges Arise in the New Shortage Economy

Previously, the organizations mentioned were using manual, mundane processes that were inefficient for their team, suppliers, and customers. By shifting away from the standard spreadsheet to prescriptive analytics, visibility is enhanced across the organization and a clear picture is given as to what each individual needs to know or do ahead of time.

“Lean DNA has allowed us to just identify those shortages upfront and start working on those issues. And I'm guessing we probably block around 95% of the noise from the plant now, the plant being our direct customer from getting materials, too. So it's just allowed us to be a little more Proactive in how we manage the business.” -Andrew Shoppa, Supply Chain Manager at HNI Corporation

Each of the participants discussed how they have begun their digital transformation by utilizing LeanDNA’s response-planning platform to streamline processes and optimize their supply chain.

How Industry Leaders are Leveraging Supply Chain Management Solutions to Create Sustainable Strategies

Top manufacturers are utilizing augmented intelligence over business intelligence solutions to generate a purpose-build workflow. Response-planning solutions are designed to be human centric to enable collaboration and better decision making.

Traditional processes centered around network design and planning do not produce actionable insights. It can be quite difficult to plan ahead or pivot strategies with the current business intelligence reports manufacturers are using. To proactively manage supply chain inventory, manufacturers are turning to automate manual tasks for streamlined, standardized procedures with clear visibility across teams.

Supply chain workers are able to reduce repetitive, time-consuming tasks to focus on the information that matters and lighten the cognitive overload that employees are feeling.

“Prior to LeanDNA, our process was very manual, my team would spend a lot of time combing through data just to find those 20 needles in the haystack that were of real concern. What is really cool about LeanDNA is that it populates inventory shortages and allows you to filter them to cut out the unnecessary noise that comes with the ERP reports, to really focus on the information that matters.”

Andrew Shoppa

Supply Chain Manager at HNI Corporation

“LeanDNA’s management dashboard gives us the ability to see and understand the trends week over week. It makes it easier to analyze and communicate shortages which has been very helpful to management. It creates a lot less phone calls for me having to explain stuff because it's very apparent what the data represents."

Gordon Van Camp

Purchasing Director at The Chamberlain Group

LeanDNA is bridging the gap between business intelligence and automated intelligence by introducing an easily integratable platform that is able to yield a sustainable return on investment.

“When we implemented the LeanDNA platform we were up and running within 60 days. My team’s KPIS and goals are primarily based on a lot of the metrics that LeanDNA’s platform provides. All of my buyers’ dashboards are set up the same way so they are able to see their excess inventory, obsolete inventory, what they need to order, and their tasks.”

Deserie Marchbanks

Purchasing Manager at PSG Dover

Want to learn more details about the discussion or have questions regarding LeanDNA’s platform? We want to hear from you.

Follow the road from manual procurement processes to supply chain efficiency.

As the global supply chain becomes increasingly intertwined, many companies are looking to update their manual procurement process. To maximize supply chain efficiency, supply chain leaders are switching to high-speed, cloud-based platforms that are purpose-built and tie together the principles of lean with surviving the shortage economy.

Follow the road to high-speed efficiency.

Maximize your supply chain management software potential.

Supply chain leaders that rely on their ERP to make daily decisions are struggling to manage and maintain data to make it actionable. Most workers in the manufacturing industry are familiar with the shortcomings these systems have when looking to quickly sift through data. When it comes to managing data, it is important to overcome this to unlock the full potential of your organization. There is a simple fix to this ERP problem.

Unlock your cloud ERP.