Leadership misalignment, digital friction, and stalled AI initiatives are holding manufacturers back. ...

Discover how Modine boosted their CTB from 40% to 95% and achieved a 4x reduction in shortages within ...

Take a deeper look at what’s holding manufacturers back—and what industry leaders are doing to mov...

Building agility into inventory strategy to stay ahead of disruption and protect working capital.

Strategies for U.S. Manufacturers The manufacturing industry is once again facing a period of volatili...

The High Cost of Poor Visibility 95% of organizations have increased their spending on supply chain an...

Introducing new capabilities to help manufacturers optimize inventory, reduce shortages, and improve c...

Aligning supply chain operations with broader business goals to position supply chain as a value creator.

Supply chain disruptions cost aerospace manufacturers an average of $184 million per year, making slow...

Explore how supply chain leaders are currently utilizing AI and examine future trends in the industry.

Learn how leveraging AI, automation, and low-code/no-code solutions can revolutionize supply chain ope...

Taking action now to optimize your inventory operations can unlock capital, reduce costs, and position...

Strategies to synchronize supply and bridge gaps within the supply chain.

LeanDNA is top rated and loved by customers in the categories of predictive analytics, inventory contr...

We are honored to be acknowledged for our Best Ease of Use in two key categories: Decision Support and...

Director of Materials at Nelson Global shares strategies to help manufacturing factory leaders drive o...

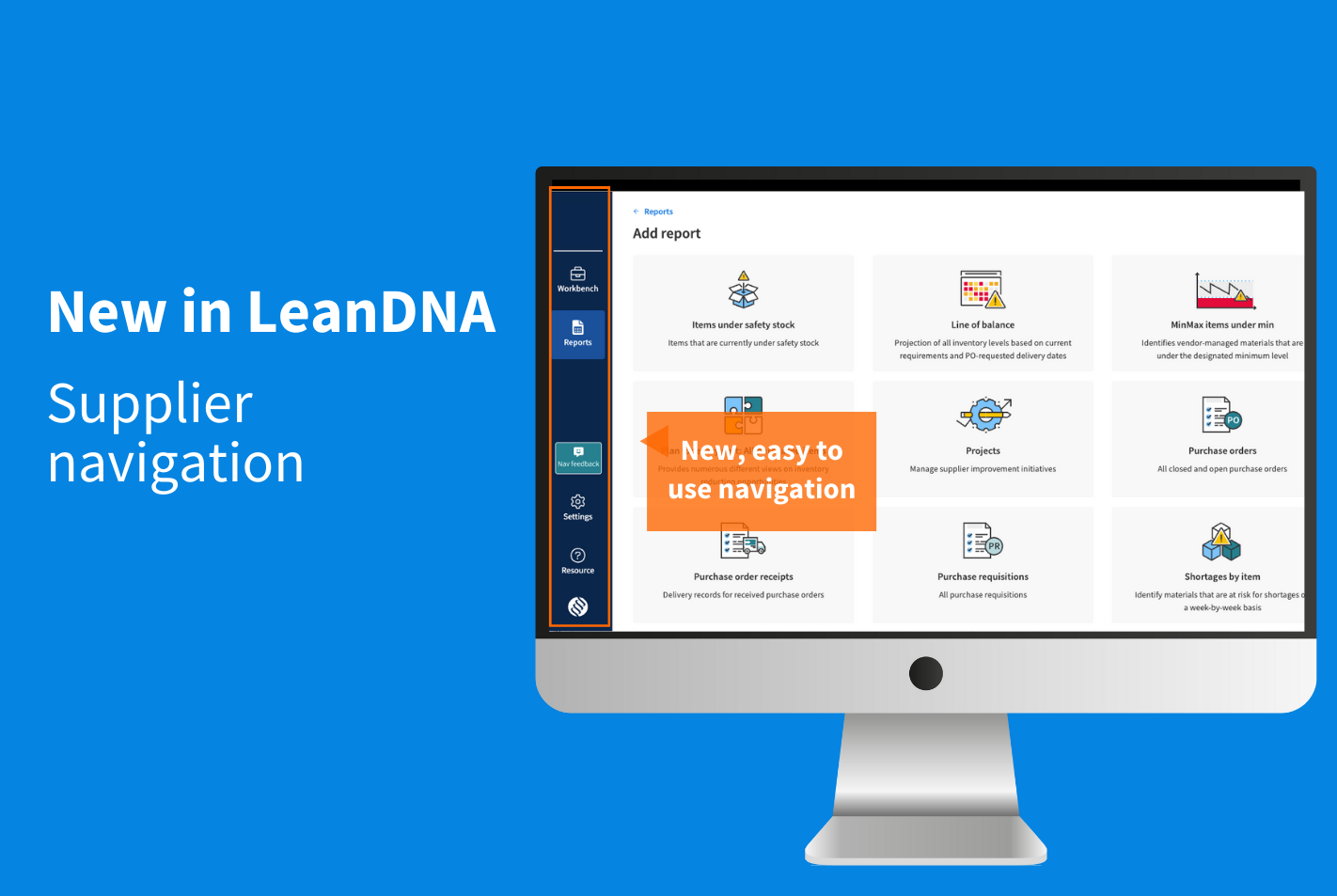

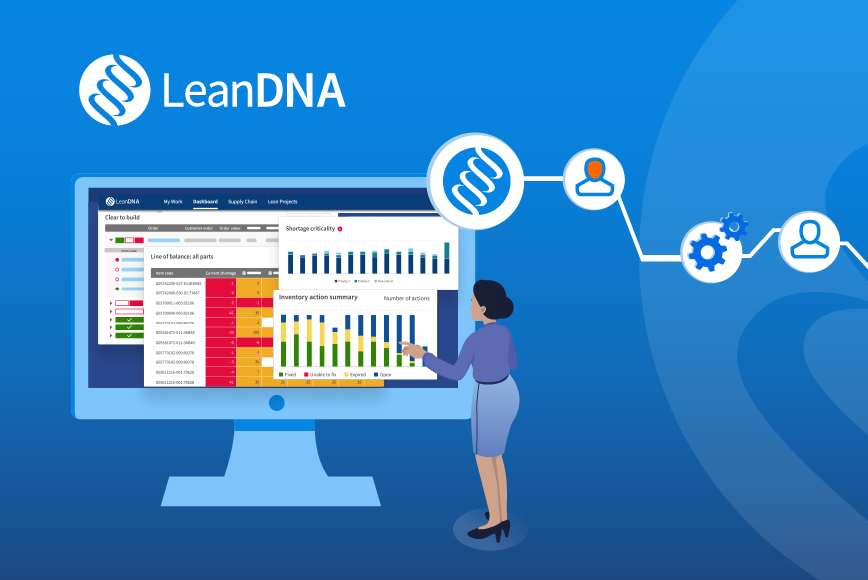

Introducing a refreshed interface that offers an intuitive hierarchy, making it easier to find the inf...

Write Back is designed to streamline the PO process, automate routine tasks, and enhance collaboration...

A financial perspective on inventory optimization.

Advanced analytics and inventory optimization revolutionize how companies handle their supply chain pr...

Balancing strategic planning with execution.

At LeanDNA, we believe that mastering our platform goes beyond just learning the basics. While our int...

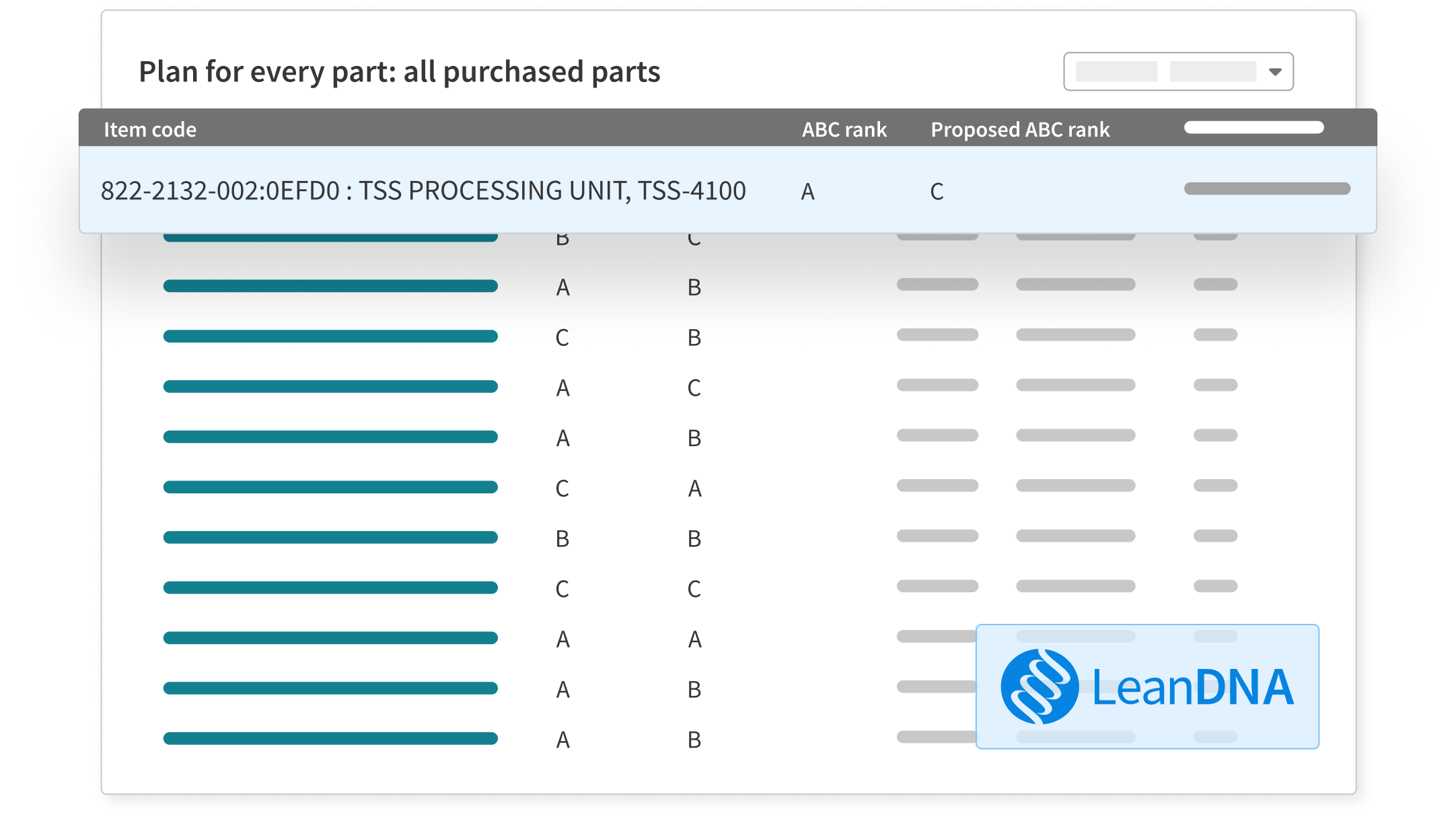

Inventory management driven by ABC analysis can enhance the efficiency of manufacturing operations.

A Strategic Approach with Advanced Analytics

Future Trends and Innovations in Supply Chain Management

Mitigating Supply Chain Risks and Building Resilience

Optimizing Inventory Management for Operational Excellence

Gain insights into navigating the challenges of supply chain management and harnessing adaptability to...

Enhancing Visibility and Collaboration Across the Supply Chain

Leveraging data-driven insights for strategic decision making

A strategic guide for achieving supply chain excellence.

Strategies for synchronizing teams, building Collaboration, and ensuring visibility

Supply & Demand Chain Executive two LeanDNA leaders with a Pros to Know Lifetime Achievement Award.

Macroeconomic dynamics & external disruptions have forced supply chain to face more challenges.

Survey of 250 supply chain executives reveals startling inefficiencies in the supply chain sector.

Leverage shortage data, define a prioritization methodology, and build a communication processes

We’re excited to unveil our redesigned supplier navigation, a significant leap forward in our co...

Replace antiquated systems and data cleanse tto improve supply chain operations

A guide for discrete manufacturing leaders to embrace digital transformation and more.

Unlock efficiency in your supply chain with LeanDNA's recent platform enhancements.

5 ways to strengthen supply chain efficiency and build business resilience.

NextGen End User awarded by reducing shortages and material shortage downtime with Clear to Build

Manufacturing companies grapple with challenges that hinder supply chain optimization. Leading organiz...

Supply chain teams leveraging technology to improve decision making and further developing their workf...

Learn effective strategies to improve your supplier relationships and reduce operational headaches.

LeanDNA Named Digital Transformation Award Finalist for 2023 Supply Chain Excellence Awards

Do You Need to Reduce Inventory Costs? Inventory management plays a pivotal role in the success and pr...

Ways manufacturers Can leverage automation to achieve supply chain excellence

The pivotal change towards automation in the manufacturing supply chain workflow

News Release LeanDNA was nominated in the Collaborative Ecosystems Category, recognizing its work with...

The importance of efficient and accurate supply chain reports

Efficient operations, reduced costs, improved customer satisfaction, and increased profitability.

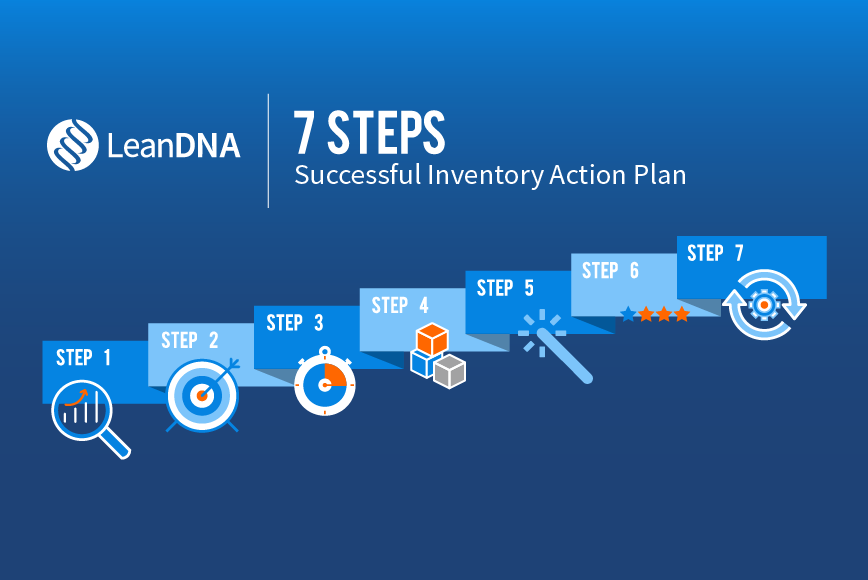

Inventory action plans streamline supply chain, optimize stock levels, and minimize costs.

Learn how automation can revolutionize supply chain management.

You could be losing out on thousands of dollars by not having a strategic supplier management framewor...

Discover strategies to tackle material shortages and drive efficient decision-making

Sustainable manufacturing best practices

2023 Data Breakthrough Awards

Enhance Clear to Build Visibility

What does it mean to have an orchestrated supply chain? Supply chain orchestration is essential in end...

What can manufacturing leaders to address demand decrease and costs increase created by inflation

Maintaining high-quality ERP data is an ongoing requirement, and LeanDNA can help you get there.

Labor Shortages Rise Due to the Manufacturing Skills Gap

The 6 necessities for successful digital transformation according to Gartner

Manufacturing Supply Chain Solutions for Inventory Management Optimization

Built In announced that LeanDNA was honored in its 2023 50 Best Startups to Work for in Austin, TX

A look back to a very succesfull year for LeanDNA's customers

Siloed data is wreaking havoc in the global supply chain and isolating your teams

Static spreadsheets are the enemy of advancement in the global supply chain

Innovative technology prevents information overload that today’s manufacturing employees are facing

LeanDNA congratulates HNI for their 2022 NextGen End User Award for Analytics.

Richard Lebovitz accepted into a community for world-class CIOs, CTOs, and technology executives.

With 3-year revenue growth of 178%, LeanDNA is among America's fastest-growing private companies

3 steps for improving communication with your suppliers to strengthen your manufacturing partnership

How to identify bottlenecks in manufacturing. Temporary vs sustainable strategies

Webinar Recap Recently, LeanDNA had the opportunity to host a discussion of the new shortage economy a...

This week LeanDNA and The Association for Manufacturing Excellence (AME) hosted a webinar on the curre...

The methods and practices that made manufacturers successful decades ago don’t cut it anymore. An in...

In 2022, manufacturers are still reeling from the ongoing effects of COVID-19, unprecedented global su...

New report reveals that manufacturing’s existing processes are in need of an upgrade

The Association for Manufacturing Excellence and LeanDNA Release Data on New Shortage Economy

LeanDNA helps manufacturers address supply chain challenges

For a third year in a row, LeanDNA is recognized as one of Austin’s “Best Places to Work”

Establish a long term solution to solve for materials shortages

How IT teams can release bandwidth when dealing with supply chain technology in manufacturing

Discover which roles play a part in managing supply chain shortages in manufacturing

Three areas manufacturers should prioritize for supply chain visibility, optimization and efficiency

Spirit Aerosystems standardizes workflows to maximize team efficiency

LeanDNA’s Platform Recognized by Global Aerostructure Manufacturer, Spirit Aerosystems

By implementing an additional analytics engine, ERPs can achieve their full potential.

Breaking down silos and ensuring the best data and communication is prioritized

SaaS has quickly proven to be a game changer in navigating the complex manufacturing landscape

See levels of responsibility that businesses can achieve as they grow their sustainability practices

Catherine Plumail recognized as an A-Lister for achieving total alignment across sites

The XYZ analysis provides a layer of statistical analysis that is essential to optimizing inventory

At LeanDNA, highlighting our Leaniacs’ successes is one of our great honors. It is with great pleasu...

Successfully managing inventory can be difficult. There are many moving parts, from determining the le...

Inventory optimization provider recognized for innovative solutions that keep manufacturers resilient ...

Increased sustainability can be extremely beneficial for manufacturers. A focus on sustainability can ...

COVID-19 disrupted lean supply chain management processes on a global scale, with unpredictable custom...

While there is no “quick fix” forshortages, there are ways manufacturers can prevent them

A conversation between Supply Chain Matters' Bob Ferrari and LeanDNA's Richard Lebovitz

"Shortage” and “stockout” are used interchangeably. Although similar, they are actually different

Backorders might be common in a modern, complex supply chain; however, they don’t have to be

The silver lining behind the high demand fluctuations and increasing inventory shortages

The new hybrid approach to inventory management

This is the 3rd blog outlining the three focus areas for optimal factory operations management.

How minimizing obsolete inventory improves sustainability

Customer Success Teams recognized for providing continuous value to manufacturers

2021's Inc. 5000 Series: Texas list of the fastest-growing private companies ranks LeanDNA at No. 57

30-year industry veteran recognized for empowering supply chain teams with best practices and tech

Leading factory-focused inventory optimization provider recognized for competitive compensation, colla...

See how AI boosts inventory efficiency for medical device manufacturers.

Cross-site visibility and access to inventory data enables leading specialty product manufacturer to b...

The LeanDNA-List celebrates the hard work of our customers, who day-in and day-out work to optimize i...

Supply Chain Management Review Names LeanDNA 2020 NextGen Supply Chain Analytics Award Winner

LeanDNA now has manufacturing’s first best practice, role-based workflow capabilities

How Can Plan for Every Part (PFEP) Help Optimize My Supply Chain? As supply chains grow increasingly c...

E-One leaders recognized for data-informed decision-making & complete alignment toward company goals

“Tackling our critical shortages using LeanDNA’s automatic shortage prioritization helps us ...

Tony Gonzalez recognized as an A-Lister for continuously leading his team to lasting results

One of fastest-growing companies in Texas: 422% two-year growth and $15 million Series B funding

Ben Galka recognized as an A-Lister for setting his team up for long-term success

NextGen Supply Chain Awards honors LeanDNA as supply chain analytics award winner

AUSTIN, Texas (Jan. 10, 2020)—LeanDNA announced today that its LeanDNA Factory Analytics manage...

Download Full story The LeanDNA-List celebrates the hard work of our customers, who day-in and day-out...

There is no excerpt because this is a protected post.

AUSTIN, Texas (Dec. 03, 2019)—LeanDNA, a purpose-built, prescriptive analytics platform for factory ...

AUSTIN, Texas (Dec. 03, 2019)—LeanDNA, a purpose-built analytics platform for factory inventory mana...

The LeanDNA-List celebrates the hard work of our customers, who day-in and day-out work to optimize in...

Download Full Story The LeanDNA-List celebrates the hard work of our customers, who day-in and day-out...

LeanDNA will deliver advanced inventory analytics, supporting Spirit’s on-time delivery goals AUSTIN...

National Manufacturing Day: A day dedicated to celebrating modern manufacturing and inspiring future s...

The Secrets to Lean Six Sigma Coaching The LeanDNA-List celebrates the hard work of our customers, who...

Safran Seats GB transforms supply chain operations with LeanDNA’s factory management technology

The LeanDNA-List celebrates the hard work of our customers, who are focused on supply chain management...

Every day, supply chain leaders from around the world tell us about their struggles with dirty ERP dat...

As the supply chain leader of a large multisite organization, how do you organize and drive an effecti...

The manufacturing and distribution environments are becoming more complex every day. Where 20 years ag...

In a recent Supply Chain Management Review study exploring the information and analytics needs of supp...

Maximizing efficiency of supply chain processes In a new special edition white paper, the Supply Chain...

From localized factories to working around the globe. The future of supply chain discussed.

Hello from Chicago! I’m here attending the APICS 2018 supply chain conference, and I’m spending ti...

How Zodiac ditched the manual spreadsheet processes and saved millions.

LeanDNA is featured in this article in Modern Materials Handling on MES.

This infographic shows the evolution of supply chain: From descriptive to collaborative

I just finished my first day at the Supply Chain Insights Global Summit in Philadelphia and spent the...

Explore the evolution of supply chain: Descriptive, predictive, prescriptive, and collaborative

LeanDNA's perspective featured in Logistics Management's MES and WMS merger discussion.

Explore insights on digital transformation with TechRepublic's guide featuring LeanDNA.

As part of a company-wide initiative to reduce working capital and inventory costs, your leadership ha...

Supply chain executives are always on the hunt for improvements to efficiency that lead to cost saving...

LeanDNA in the news! Recently, LeanDNA Founder and CEO Richard Lebovitz was interviewed by Yitzi Weine...

Supply Chain Insights Can Identify Opportunities to Enhance Performance How do you use supplier insigh...

When manufacturers talk about inventory turnover, they’re referring to how quickly their company can...

LeanDNA's multi-site visibility brings together all manufacturing ERPs and sites into one dashboard

Does your team have the critical supply chain reports necessary to optimize inventory? Picture this, S...

Does your factory have ERP purchase order overload warning signs? Here are 4 most common signs

Inventory ties up a massive amount of working capital – to the tune of $459 billion dollars. That ma...

Best Practices for Aligning Your Procurement Team and Supply Chain Strategy for Continuous Improvement...

Advanced analytics allow manufacturers to see and interact across sites like never before

French joins English, Spanish, and Chinese as officially supported languages within LeanDNA.

Why Automation? Advanced Inventory Reporting and Supply Chain Analysis Solutions Your car’s dashboar...

Tools for supply chain management improvements “Coming together is a beginning; keeping together is ...

Get a first hand look at what LeanDNA implementation looks like from an IT team’s perspective

Elevate your supply chain game with expert data cleansing insights.

Unlock the power of ABC analysis for smarter purchasing decisions.

Are You looking for Ways to Maximize Your Supply Chain Management Software Potential? Get the benefits...

Lean Manufacturing 101: Do you know the basics?

Discover how leading aerospace firms are integrating techn to boost operational performance.

Shift from one-way to collaborative analytics for better decision-making and efficiency.