When manufacturers talk about inventory turnover, they’re referring to how quickly their company can process the parts inventory in its warehouse. Most track it by turnover ratio, which equals the cost of goods sold (COGS) divided by inventory. The higher the ratio, the faster the company will reduce inventory and the less money is tied up in inventory capital. Additionally, the company saves on storage costs and is better able to avoid part obsolescence.

In the world of supply chain, buyers are often focused on avoiding supply shortages. After all, an unexpected disruption has the capability to completely halt production, costing the company millions in expedition fees, lost revenue, and work inefficiencies. In this light, it makes perfect sense for a buyer to prioritize higher inventory levels over inventory reduction strategies. No one wants to be responsible for inadvertently causing a shortage.

On the other hand, managers and executives are held accountable to a different set of KPIs. When an executive walks into a board or shareholder meeting, they must account for the millions of dollars in capital tied up in excess inventory. Legitimate questions are raised about why those numbers are so high and what inventory reduction strategies are in place.

Every business understands the importance of improving inventory turns, but only some implement truly effective plans to address it. For supply chain team members at all levels, the most effective first step toward improving turnover is to optimize (usually, reduce) inventory. So how do large, complex systems with multiple international sites and dozens of stakeholders effectively focus on reducing inventory?

1. To Reduce Inventory, Start From the Top

Inventory optimization efforts are by far most effective through a top-down approach. Too often, a disconnect exists between the priorities of managers and buyers. It's the responsibility of executives and managers to create a culture of urgency around reducing inventory levels. This starts with setting and communicating clear goals at every level of the supply chain.

Step one for any leader is to emphasize the importance of the KPI. But another valuable thing you can do for your team is to attach a potential savings value to each task. This linkage between individuals and savings helps improve accountability throughout the team and is most effectively achieved using a singular tool.

It is critical to develop and articulate inventory level goals. Some supply chains shoot for a 10% overall inventory reduction is enough; others should aim closer to 15%.

Setting clear goals and creating a culture of accountability is far more feasible with an advanced prescriptive analytics tool. Manual spreadsheet and macro processes are neither fast nor smart enough to provide the real-time synthesis needed to optimize inventory for every part in real time. Managers need smarter tools.

A top-down approach to a goal-focused culture creates unification throughout the company. It connects multiple sites in different countries with different ERP and buying systems. And it communicates common goals, creating accountability for how they’re being accomplished.

A top-down approach to a goal-focused culture creates unification throughout the company. It connects multiple sites in different countries with different ERP and buying systems. And it communicates common goals, creating accountability for how they’re being accomplished.

How do you kickstart a top-down approach to inventory reduction at your company? Make sure you’ve got the right tools in your arsenal, from buyer to CEO. Team members should have prioritized inventory tasks assigned, with a dollar value attached to each task. That way, everyone knows the value they’re expected to drive (or better yet, achieve!).

Then, through one consolidated dashboard, managers should be able to view progress and real savings values for each task across all departments, business areas, and manufacturing sites. Real savings data needs to be updated daily and available in real time from anywhere in the world. LeanDNA does this, and we’ve found that this process can help reduce inventory by 10% in the first 90 days alone. And since it’s not a one-time solution, gains are sustained for months and years

2. Equip Teams With Smarter, Automated Work

One reason for the lack of urgency in tackling inventory reduction has to do with how labor-intensive inventory optimization processes are for many supply chain teams. Most systems rely on manual spreadsheets that require hours of work for buyers and analysts just to get a retrospective view of their inventory data. Real-time document collaboration is unavailable to the majority of supply chain groups, making decision-making far less effective.

Per direction from upper management, teams often focus most of their energy on exception message management. This is theoretically a fine strategy, but the effectiveness is significantly diminished in practice when buyers receive thousands of messages every week. Which messages are most urgent and which can be addressed at a later date? How do teams decide?

One aerospace company we worked with implemented a system that involved analysts manually combing through hundreds and hundreds of messaging outputs every week - to the point that entire teams were working through the weekend just to stay caught up with their ERP messaging! Needless to say, this is far from efficient.

A major step toward drastically improved inventory turnover is to equip supply chain teams with the best tools for the job. This means implementing a solution that provides a single dashboard with reporting and messaging. It should be collaborative, and data should be real time. This lets you employ advanced, prescriptive analytics that provide decision-making support by prioritizing messages in order of business value.

It also means optimizing order policies according to changing demand. Most supply chains set order policies based on one set of demand values, but lack the agility to adjust policies as the demand environment fluctuates. Again, manual processes are a primary hindrance to improved inventory turns. How many hours, days, or even weeks does it take a team to find and collect the right data, much less understand and act on it?

It is critical to use a tool that provides cross-site collaboration among all teams. Many multi-site supply chains employ several different ERP systems and dozens if not hundreds of disparate processes. A buyer or analyst at one site has almost no chance of collaborating with team members at other sites. In today’s world of highly complex supply chain systems, successfully improving inventory turns necessitates seamless, real-time inventory collaboration across multiple sites.

To do this, you of course need to be able to collect and analyze demand data. But why stop there? Modern technology uses AI and machine learning to provide recommended ordering actions based on advanced predictive analytics.

Recently, one manufacturer sought to identify the top ten opportunities to reduce inventory across their multiple sites. They wanted to see the opportunities, understand the root causes, and identify who should be responsible for addressing each. Through the LeanDNA tool they were able to connect multiple systems, rank opportunities by value, and equip analysts to engage at a global level across the entire business.

3. Improve Inventory Turnover With ABC Analysis

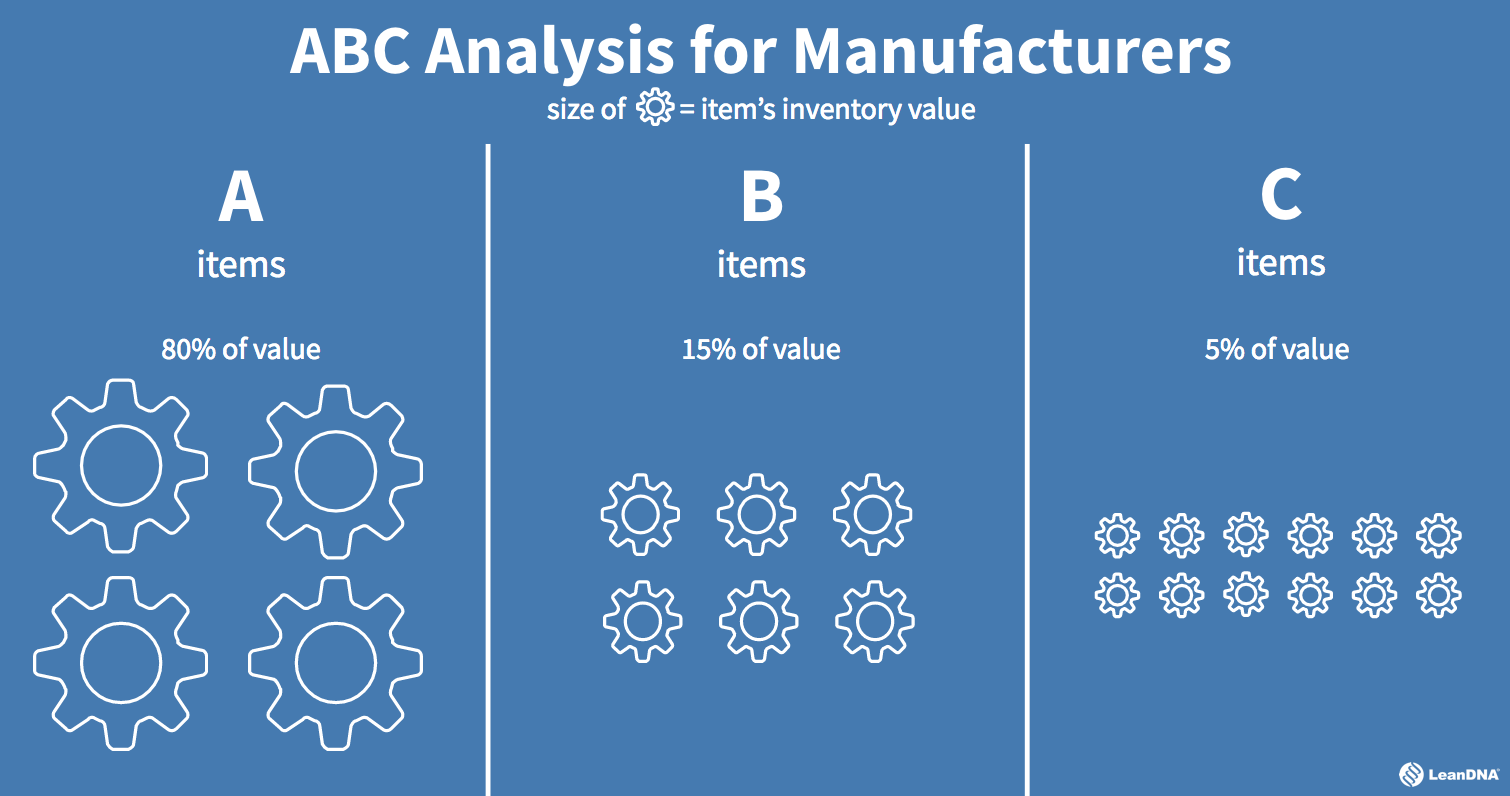

In order to get the absolute most out of inventory optimization efforts, it is critical to focus on the parts that cost the company the most money. Performing an ABC analysis (also known as RRS, or Runner Repeater Stranger) helps draw a manager’s attention to the few parts that are most valuable, rather than the many other parts that don’t have as much impact on working capital. An effective ABC analysis helps keep costs under control by improving inventory efficiency for those critical items.

Utilizing the Pareto Principle, a manager can identify the 20% of parts that make up 80% of an inventory’s total consumption value. These are the “A” items, and the group that is deserving of the most scrutiny and optimization efforts. These should have tight inventory control measures with more frequent orders. Many supply chains prioritize higher stock levels for these parts, thinking it best to avoid shortages, but their reports often reveal that “A” items are overstocked, tying up millions in unnecessary inventory capital. There’s a lot more to ABC analysis, so check out our full guide here.

Utilizing the Pareto Principle, a manager can identify the 20% of parts that make up 80% of an inventory’s total consumption value. These are the “A” items, and the group that is deserving of the most scrutiny and optimization efforts. These should have tight inventory control measures with more frequent orders. Many supply chains prioritize higher stock levels for these parts, thinking it best to avoid shortages, but their reports often reveal that “A” items are overstocked, tying up millions in unnecessary inventory capital. There’s a lot more to ABC analysis, so check out our full guide here.

ABC analysis is another place where supply chain technology can drastically improve inventory turnover KPIs. Instead of performing this analysis by hand on a less-than-regular basis, tools can automate this process for you to make sure your A items are being treated like an A item should. From there, you should be able to process those results to identify action items that help reduce inventory, including multi-site item redistribution and order policy changes.

A good ABC or RRS analysis will equip your team to avoid shortages and optimize inventory levels for every part across all your sites. And I bet you’ll see inventory turnover ratios improve drastically along the way!

4. Take a Bird’s-Eye View

Agility is the name of the game, and teams rely on their tools to provide it. How can leaders make the best decisions without the most accurate and up-to-date information? They must ensure the reports they need are readily available and it’s critical for an executive to have a high level view of the health of the supply chain across all manufacturing sites. Mining ERP data is not enough - manual spreadsheets and macros can only provide so much insight.

An AI-based reporting dashboard provides the most accurate and up-to-date information that supply chain leaders need to make critical decisions for their organizations. It allows them to view the most valuable reports in real time from anywhere in the world and make decisions that have immediate impact on the bottom line, specifically on inventory turnover. For example, executives can view accurate inventory data across multiple sites, while site managers can use the same solution to not only see but act on inventory challenges before they become crises. The system shares inventory data across sites, allowing analysts to alleviate shortages at one site with excess inventory at another.

Consolidating to a single dashboard analytics solution creates a scenario where all stakeholders are able to act with more agility to address challenges quickly and using the most accurate information. Instead of days or even weeks of information delay, they receive up-to-date information within hours of it being available. And AI-based prescriptive analytics provide not only a forecast, but recommended action items that make inventory optimization simple and straightforward.

For example, when excess and shortage reports are available in real time and across multiple sites, actions can be taken more quickly to alleviate a shortage at one site with excess inventory at another. This saves the cost of premium part prices and improves inventory turnover by reducing overall inventory. A true bird’s-eye view of that brings all of your sites together can significantly benefit your bottom line!

5. Tap Into Continuous Improvement Expertise

Some challenges arise without an immediately clear solution. Particularly pesky problems can become recurring headaches for weeks or even months. Uncovering a solution requires a deep dive into data analytics and root cause problem-solving. For problems like this, a team of Lean or Six Sigma experts often proves invaluable. Using industry best practices, these experts provide direction for how teams improve their work.

This is where prescriptive analytics is most valuable. AI-based analytics provide an outlook on the future and recommended action items that are based on accurate data and industry best practices. This makes continuous improvement efforts more streamlined and easier to implement. Utilizing a single dashboard for the entire company means that all teams use the same standardized work, improving efficiency and cross-site collaboration.

After you’ve used your analytics to identify any issues, the next step is to create cross-functional projects to fix the broken processes. This equips stakeholders with visibility into ongoing lean projects, and align KPIs with strategic initiatives. All performance should be tracked in real time, allowing all staff members to collaborate directly within the project management platform. We don’t need to tell you that lean works for manufacturing (70% of manufacturers use lean practices), so get continuous improvement integrated into all of your supply chain processes.

Wrapping It Up

There is significant cost-saving opportunity for complex supply chains by optimizing inventory levels, positively impacting inventory turnover, for every part in the system. It is tempting to focus on avoiding shortages because of how chaotic and costly they are, but improvement in the long term requires a deep dive into improving inventory turnover, which means you need to reduce inventory levels and costs across the board.

Dealing with material shortages can be made easier using advanced analytics to improve supply chain collaboration.

While there are best practices for preventing and deal with a material shortage, there are new advancing technologies emerging that automate some of the manual processes used to deal with these challenges. By freeing up supply chain worker’s time, companies can reduce burnout and free up opportunities for their employees to utilize their skills in more efficient ways.

Learn how you can use analytics to deal with material shortages.

It’s time to make lean supply chain management stick.

Have you ever spent tons of time planning and executing a new lean project, only to have it lose steam down the road? When developing a lean continuous improvement process, it is important to consider not only what the best practices are, but how to implement them in a way that really sticks.

Learn more.