Key Differences Between Shortages and Stockouts

Oftentimes, the terms “shortage” and “stockout” are used interchangeably. But they are actually two different—yet extremely similar—things. To understand the difference, we must look at the two terms separately.

What is a stockout?

According to Shopify, “stockouts can be defined as the unavailability of specific items or products at the point of purchase when the customer is ready to buy.” Some people also call this out-of-stock. The unavailability of products leads to a reduction in customer satisfaction and reduced brand loyalty, so it’s in the company's best interest to avoid stockouts. Take for example the global chip shortage occurring right now due to a “perfect storm” of events: a global pandemic, fires, snowstorms, a canal blockage, you name it. These chips are an integral part of many different products that without them, can’t be produced. This stockout affects many different markets including the auto industry, consumer electronics, and even refrigerators.

What is a shortage?

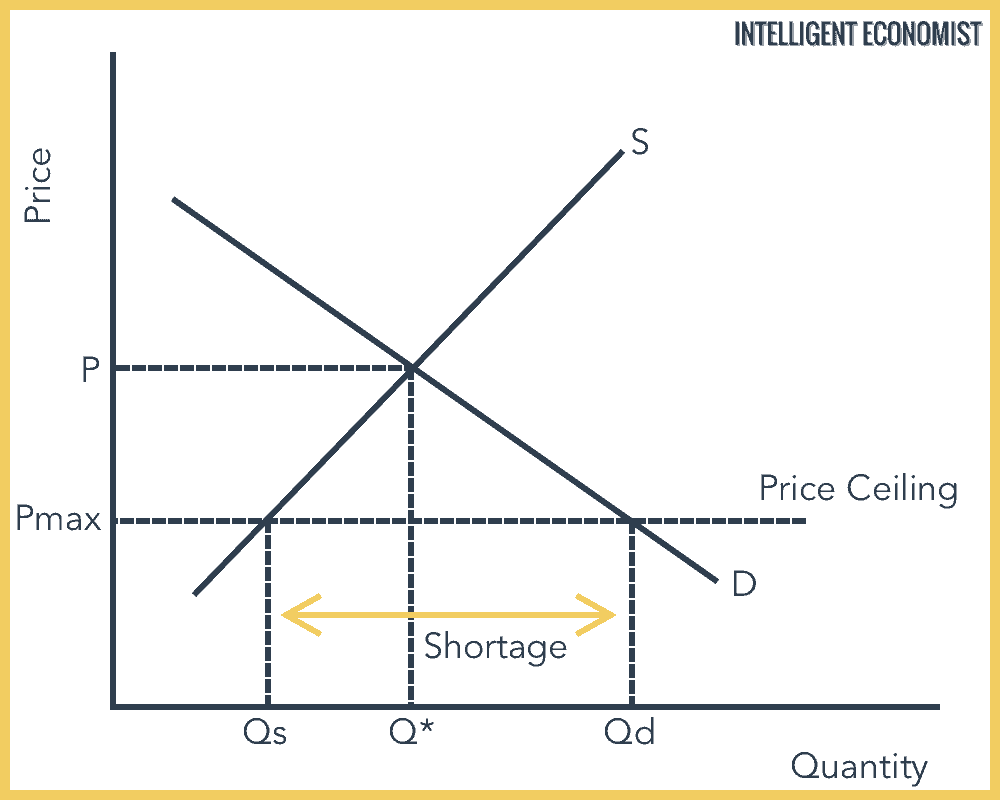

A shortage, in economic terms, means that the quantity demanded is greater than the quantity supplied. The market is not at equilibrium and more people want a product than can actually get it.

Shortage management is the process of reviewing your current supply and demand, and adjusting your schedules or expediting orders to ensure you can continue production. A shortage can occur, for example, during an unusually hot Texas summer when there's an unexpected demand increase for inflatable river tubes. Suppose the manufacturers didn’t account for this unexpected surge in orders—this would cause a shortage of tubes. For an online retailer, if they do not clearly mark the product out-of-stock and refuse orders, the product will be back ordered, meaning the order has already been placed but the product is temporarily unavailable.

Shortage vs. Stockout - What makes them different?

The term “shortages” is general and can be used to describe many different situations—from manufacturing part shortages to labor shortages. It can be applied to products, services, or even just conversation. A “shortage of vitamin D” may lead to a deficiency, which makes more sense than saying a “stockout of vitamin D.”

The term “stockouts” is specifically used to describe the absence of a part or item that is needed to produce another item or serve a customer. This could be like the missing computer chips suppliers need to complete products or just an item at a brick and mortar location that is out of stock. Typically, stockouts and shortages are happening in the present—there are current shortages of a part impeding delivery. However, manufacturers may use the terms to describe potential upcoming shortages in their factories due to known disruptions in their supply.

8 Causes of Stockouts or Shortages

There are many challenges in the manufacturing industry that could lead to inadequate inventory levels. Some of these challenges include:

1. Unexpected Events or Increases in Demand

There are many different factors that can influence levels of demand. Weather, recessions, or even just fads and trends. Drastic changes in demand can be off-putting for many suppliers if they are not predicting an increase. As for unexpected events, we have all seen the huge impact COVID-19 had on supply chains. Supply chains are greatly affected by factors outside of the manufacturer’s control. The only way to maintain a resilient supply chain is to get factory operations teams ready for whatever comes next.

2. Capacity

If a supplier does not have the appropriate capital to handle increases in demand—whether or not it is unexpected—the industry as a whole will experience shortages due to the lack of supplier capacity to make a product. But lack of capital at one supplier is just one example of capacity issues. There may also be limited capacity to make certain items due to a lack of technology or cost-effective technology, the complexity of manufacturing (think: Aircrafts), or even the skilled labor needed to make certain products.

3. Government Intervention (Price Ceilings)

Government intervention in pricing can greatly impact the flow of the market. When a price ceiling is imposed, a price maximum is put into place. Since this ceiling is typically lower than the equilibrium price, suppliers will produce less, or won’t produce at all. Consumers then demand more because the price is lower than the typical cost at optimized market equilibrium. This leads to disparities in the quantity demanded and quantity supplied of the product that has the price ceiling.

4. Product Quality Issues

When product quality is not up to par, the seller can’t sell the item, and the manufacturer who needs it can’t produce their goods. The majority of the time it will get sent back to the supplier, causing delays in production at the facility and product availability to the customer. Typically, a seller counts on quality products to arrive. When they don’t, the item is displayed as out-of-stock.

5. Production Scrap

Potentially related to product quality issues—and perhaps internal manufacturing process issues—a product’s components are damaged beyond repair and must be scrapped during production. Product scrap causes unexpected shortages unless there is a known or accepted scrap rate for a particular part a manufacturer has planned for. Otherwise, buyers are left scrambling to purchase more.

6. Late Delivery

Despite suppliers' best intentions, sometimes a delivery just doesn't arrive on time. If you are a company that orders just enough products to fulfill daily, weekly, or monthly sales (depending on your schedule), this delay in delivery time can create shortages. If left unchecked, those shortages can cascade throughout operations and down the supply chain.

7. Under-ordering

When organizations lack visibility, they underestimate how much stock is required to fill all orders without having excess lying around the warehouse. Often, they will under-order, leaving consumers unfulfilled and upset.

8. Material Handling Backlog

Some shortages are caused by a material handling backlog in the receiving department. Parts might sit in a box on the receiving docks, and handlers must sort through all of the boxes to log into the system so they can be properly accounted for.

The difference between the shortages and stockouts is nuanced and contextual. Looking for more information? Discover more about preventing shortages in “How to Deal With Material Shortage Using Analytics and Collaboration.”

LeanDNA helps prevent shortages by automating and standardizing your shortage reporting to save your team hours of manual work. Discover the industry's first inventory optimization workflows.

FAQ

What is a sudden shortage of goods called?

A sudden shortage of goods is called a stockout. This means that at the point at which the customer is looking to purchase, the item is unavailable.

What is the difference between a shortage and a stockout?

The term shortage is more general and can be used to describe many different situations in different industries or areas of life. The term stockout is more specific and typically only used to describe the absence of a part or item that is needed to produce another item or to serve a customer.

What are some causes of shortages?

Unexpected increases in demand, unpredictable events, capacity issues, government intervention, product quality issues, production scrap, late delivery, under-ordering, and material handling backlog are all potential causes of shortages.

Is a stockout the same as a backorder?

A stockout is not the same as a backorder but can lead to it. When there is a stockout or shortage, a product typically becomes unavailable for a seller to provide. If an online retailer does not clearly mark this product out of stock and/or remove the ability to order it, customers will still order the product and it will lead to the product becoming back ordered.

Want to learn more about shortage risk management?

Whether you are trying to reduce shortages or stockouts, the impacts of both can be detrimental to your business by delaying production’s timeline and diminishing customer satisfaction which ultimately impacts revenue.

Discover ways to avoid, adapt, and absorb the impact of supply chain disruptions

Shortage reduction is no small task.

Hysecurity, a leader in the manufacturing industry, improved their on-time delivery with 83 percent shortage reduction in 3 months.

See how Hysecurity improved their customer satisfaction