Case Study | MSA Safety

The mission of MSA Safety (NYSE: MSA) is to help protect people at work so that “they, their families, and their communities may live in health throughout the world.” It is a mission that hasn’t changed in 110 years. This is why it is important that their manufacturing operations run smoothly with fast turnaround time and high performance.

Industry-Wide Supply Chain Challenges

78.3% of manufacturing leaders surveyed by The National Association of Manufacturers listed supply chain issues as a primary business challenge. MSA Safety, like a majority of manufacturers, was impacted by the ultra-constricted supply chain environment following the pandemic.

To help address these challenges, the global leader in safety took the initiative of implementing technology and new strategies that maximize supply chain value and efficiency.

Building Resilience through a Digital Supply Chain Transformation

Many MSA Safety offerings are configurable products and solutions that are assembled to meet the unique needs and preferences of customers. MSA defines this manufacturing process as Assemble-to-Order (ATO). While the ATO process helps MSA meet customer demands, it also comes with various supply chain challenges, such as forecasting configurable options, lead time extensions, and single-sourced components.

The reason that a large number of manufacturers are facing this challenge is that traditional processes are no longer effective in the new, post-pandemic state of the supply chain.

“Consignment programs that used to be effective just don’t work in this environment and we’ve had to learn to adapt and make changes,” said Eric Blanton, MSA Safety Global Purchasing Manager. “It was apparent that if we continued to use certain legacy processes, our inventory visibility would become static in this new environment, and that would present a new set of challenges.”

Why Manufacturers Need to Upgrade Their Technology Stacks

Although ERP systems have historically been great for housing large sets of data, the increased complexity and globalization of the supply chain have decreased the value of legacy solutions.

While ERPs are essential, they can be limited in visibility and collaboration capabilities for execution. With hundreds of ERP notifications and a variety of different reports and spreadsheets, it can be overwhelming to keep track of changing and competing priorities.

“We use a robust SAP system, but it has certain limitations when it comes to seeing details related to on-hand and incoming inventory.” Jessica Troiano, Chief Procurement Officer for MSA Safety.

This data challenge weighs heaviest on procurement teams, who are charged with keeping pace with an ever-changing supply chain environment.

In fact, Gartner analysts reported that only 17% of supply chain buyers have the technology they need to efficiently do their jobs.

“While our ERP system supports key business functions, we discovered that we needed an enhancement to help us prioritize and make sure we are executing on the most impactful tasks, in order of importance.” Eric Blanton, Global Purchasing Manager

Sourcing & Procurement: The Secret Weapon of the Supply Chain

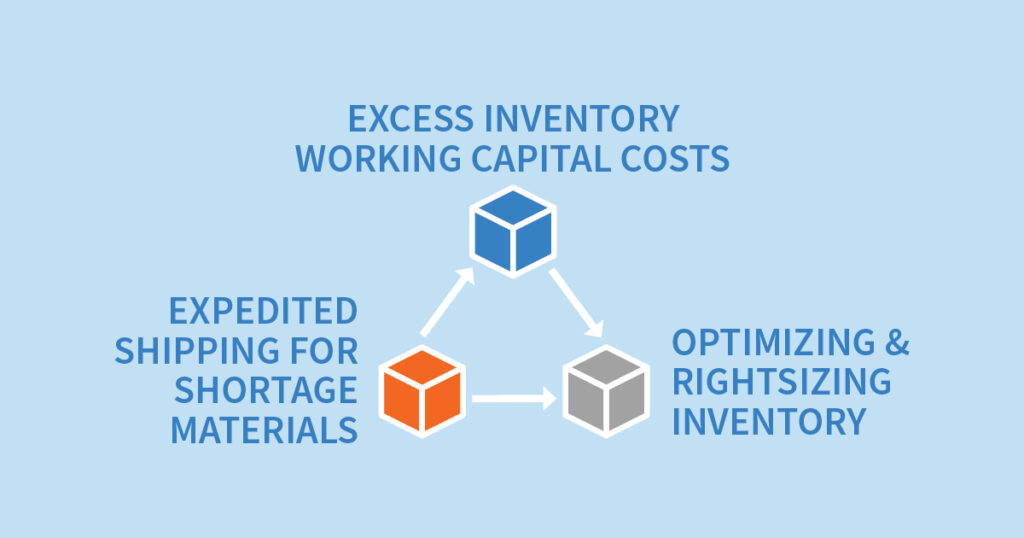

“Sourcing and procurement have never been more instrumental in the success of an organization as they are today,” says Jessica Troiano, Chief Procurement Officer for MSA Safety. “Our sourcing and purchasing teams bring so much value, particularly when it comes to getting parts in the door and on time, which is key to meeting customer expectations. We have to stay up to speed on so many different situations with our supply base to make sure we have good visibility on the parts coming in to avoid stockouts or shortages, while at the same time, managing our working capital and inventory.”

Troiano referred to this triangle paradigm of trying to balance everything for the organization.

“Time management is important. We need to keep our buyers and sourcing groups focused on the most value-added part numbers and activities, first and foremost.” - Eric Blanton, Global Purchasing Manager

MSA Safety continues to strengthen its brand and market leading positions in safety, highlighted by the company’s development of new technologies that are helping to protect workers and facility infrastructures around the world. A pillar of the MSA culture is the MSA Business System – a continuous improvement mindset grounded by processes and behaviors that touch virtually every function and aspect of MSA’s business. Using the MSA Business System, the company took on the strategic initiative to invest in an optimization and execution solution that would digitally enhance its supply chain, to gain a competitive edge in this new era.

Competitive Advantages of a Digitized Supply Chain

Innovative, automated technology reduces the workload and the time it takes manufacturers to analyze critical supply chain information by providing readily-available reports and quick access to key performance metrics.

MSA Safety saw the advantage of leveraging a centralized solution with advanced analytics to improve collaboration, efficiency, and performance to exceed their organizational goals.

After weighing various options, including supply chain management tools, MSA Safety identified LeanDNA’s inventory optimization command center as the solution that would best meet their needs.

LeanDNA is highly configurable – the cloud-based solution can connect to any ERP to create customizable dashboards and reports that provide value across procurement and supply chain teams.

LeanDNA also connects teams and technology to ensure organizations solve problems and make decisions that are aligned with their strategy. Planners, buyers, leaders, and suppliers can collaborate seamlessly with streamlined workflows, and standardized reporting.

LeanDNA enables users to work more efficiently through real-time updates and streamlined collaboration. These capabilities have enhanced MSA Safety’s centralized Purchasing Services model.

“It would not be unusual for a buyer in Pittsburgh to complete a task and then need to share information with a production planner in Jacksonville, North Carolina to minimize the potential for a stockout or to expedite a customer order,” said Blanton. “Our teams can all interact within LeanDNA’s platform – our supply planning, demand planning, production planning, buyers, and sourcing team all have access to streamline communication and improve efficiency.”

MSA Safety utilizes LeanDNA’s centralized platform to consolidate information and improve cross-functional visibility.

LeanDNA helps identify shortage risks for potential deadlocks in production ahead of time so teams have more time to prepare for supply chain disruptions. For example, the solution reveals the depth of delay for a material shortage and helps prioritize the actions that need to be taken first. “The improved, data-driven material shortage visibility helps us see down the road, and around the corner. There is improved visibility into our next supply constraint to help focus our efforts into resolution action, versus investigation,” Blanton said.

“After implementing LeanDNA, the visibility in demand forecasting becomes more clear through the platform. LeanDNA gave us an interactive picture of what changes were happening and where we had the potential for critical material shortages. Further, with access to historical data, we were better able to identify spikes in demand and why we were having shortages.” - Carl Mckinney, Buyer at MSA Safety.

LeanDNA puts key information in one place, making information faster and easier to find.

MSA Safety buyer, Sadie Myers said “The biggest challenge as a buyer is repetition. After implementing LeanDNA, we are able to leave notes on the platform and forward information to other departments, and that makes it easier to get more work done in a shorter period of time without repetition.”

“One of the biggest impacts LeanDNA has made is an increase in efficiency, it is a real time-saver.”

Another MSA Safety Buyer, Jeremy Simms, noted that a key value driver for his team is the platform’s “functionality within LeanDNA, which Jeremey and his team use to share comments, create tasks, and communicate in one centralized location to reduce emails and time spent on pulling SAP reports.”

Through LeanDNA’s standardized, role-based workflows – each team member has clearer goals and responsibilities. Buyers have clear objectives to meet their inventory goals and make sure production isn’t delayed, while leaders have a comprehensive view of everything the buyer is working on.

LeanDNA provides prioritized actions ordered by importance and criticality to help supply chain teams make decisions that positively impact short and long-term goals. Digitally enabled shortage reporting advanced MSA Safety purchasing effectiveness and improved the quality of the conversations between buyers and planners.

Supply chain leadership can track progress and identify areas of improvement through LeanDNA’s automated buyer, site, and supplier performance reports. MSA Safety’s purchasing team incorporates LeanDNA visualizations in their weekly team KPI huddles, which dovetail into their business operating system.

Even MSA Safety’s suppliers are included in the platform – through LeanDNA’s supplier connect portal and supplier scorecards using standardized performance metrics. Within LeanDNA, MSA buyers can quickly check supplier performance, including the plant they service, and their delivery scores. As a part of a continuous improvement effort, MSA is working on implementing a quality score and cost score to enhance supplier performance and collaboration. As an example, LeanDNA's Supplier Connect enables strategic suppliers to view orders and exception messages and provides a means to interact within the platform for improved collaboration, and real-time responsiveness.

Get a copy of this case study as a printable PDF. Download Now

Learn more about MSA's inventory optimization in this MSA Supply Chain Visibility Testimonial Video

Find out how you can reach new milestones in your supply chain execution.

Set up 15 minutes with one of our inventory optimization experts. Schedule a Demo

More Resources

Optimizing supply chain efficiency: Navigating challenges

Optimizing supply chain efficiency: The role of technology

On-Demand Webinar: Maximizing Supply Chain Efficiency, Collaboration, and Performance