This post was written by LeanDNA’s Head of Product, Sabari Krishnan

In today’s factories, every decision matters. Supply chain teams are fighting daily battles to keep production running, balance inventory levels, and prevent costly parts shortages, all while trying to stay ahead of constant disruption.

That’s why LeanDNA is launching APEX, the next generation of its factory-first platform for supply planning and supply chain execution. APEX is where data, insights, and actions come together in one single source of truth, so factory teams can execute with peak intelligence, precision, and domain knowledge.

Why It Matters

Manufacturers have lived for years with the same impossible paradox: too much capital tied up in inventory, yet still too many shortages blocking production. Traditional ERP systems and spreadsheets were never designed for the speed and complexity of modern factory operations.

APEX gives supply chain teams the visibility and foresight to solve that problem.

"The ability to accurately model the complex trade-off between inventory cost and service level has always been a major challenge,” said Elena Rodriguez, Global SIOP & Materials Management Director of FlowServe. “With APEX Inventory Optimization, we get the precision we need. It gives us the confidence to adjust our order policies, knowing we are maximizing our working capital while minimizing the risk of costly stockouts. This is the definition of smarter, more strategic supply planning."

What’s New in APEX

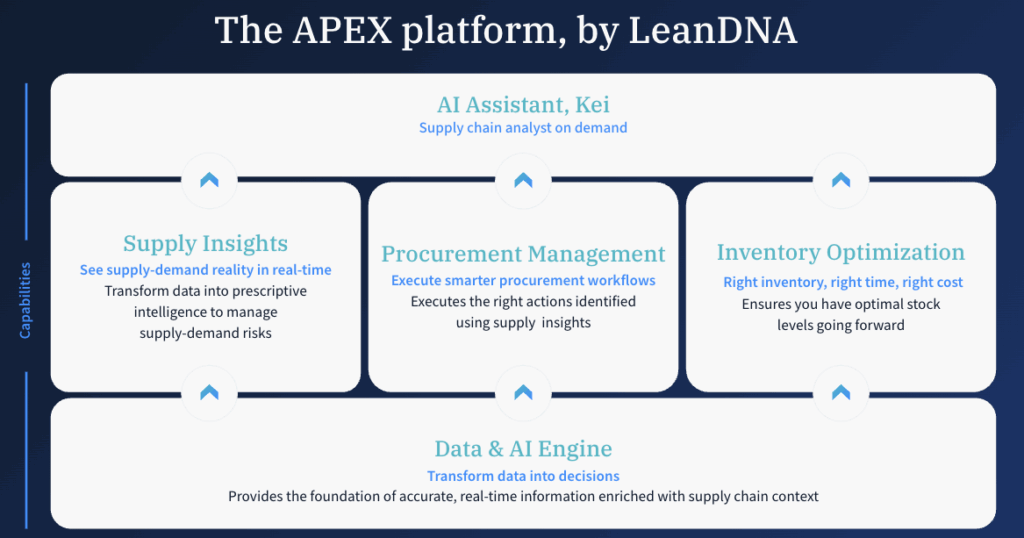

APEX unites LeanDNA’s proven capabilities with powerful, AI-driven innovations that are purpose-built for factory agility and optimized inventory levels. With the launch APEX comes three new offerings:

- Inventory Optimization

A new engine for strategic inventory management. It uses advanced AI to simulate order policies and safety stock, improving on static ABC-XYZ models with multivariate analysis that accounts for demand indicators outside of assumed predictability, like variability, frequency, trends, and seasonality. Inventory Optimization helps manufacturers maintain optimal inventory levels without sacrificing service levels or tying up cash. - Kei AI Assistant

A conversational AI built for supply chain leaders. Ask questions in plain language like, “Which suppliers are driving my parts shortages?” or “Where are my biggest risks this week?”, and Kei delivers expert, data-backed answers instantly. - Workbench

A centralized workspace for buyers, supervisors, and suppliers that drives faster, more collaborative supply chain execution. It cuts through noise by automating repetitive tasks and surfacing the most critical actions, from purchase order updates to supplier confirmations. Buyers can prioritize and act on what matters most, supervisors can track performance, suppliers can respond directly, and everyone operates from the same single source of truth.

With the addition of these innovations, APEX is now built on five core capabilities that unite data, insights, and action for every team across the factory:

Each capability connects people, processes, and systems into one unified platform. This foundation ensures the platform can continuously expand, adapting to new technologies and the changing needs of global manufacturers.

"The launch of APEX is a major step forward for supply planning," said Andy Ellenthal, CEO of LeanDNA. "We’ve taken our proven, battle-tested platform and injected powerful, net-new AI capabilities to deliver a solution that directly addresses the shortage-excess paradox. APEX empowers supply chain teams to act faster and smarter, securing their production and dramatically improving working capital."

The Results So Far

Manufacturers using LeanDNA’s platform have achieved measurable impact, proving how connected data and factory-level execution can drive real business results:

- 32% fewer parts shortages

- 18% improvement in on-time delivery

- 14% reduction in inventory levels

These results show what happens when factory teams have the intelligence, visibility, and tools to work from one single source of truth; they benefit from faster action, stronger collaboration, and supply chains that can thrive in any condition.

See APEX in Action

If you’re curious and want to learn more about how APEX transforms supply planning and execution, join our upcoming webinar sessions on November 13 and December 4.

You’ll see how the platform connects data, insights, and actions in one place, giving factory teams the intelligence and control to act faster, reduce shortages, and optimize inventory levels.