Siloed data is wreaking havoc in the global supply chain.

Without a standardized supply chain system, manufacturers are having difficulty finding, reporting, and executing information. Isolated supply chain teams are making decisions based on outdated, static data which is not only costly for modern manufacturers, but is causing barriers in reporting, prioritization, and communication. With today’s complex, global supply chains –organizations need smart factory solutions to avoid costly data silos.

What is a Data Silo?

Data silos are sets of information that is not accessible to a whole organization. Each siloed team has their own set of data and is working out of sync. Since the particular set of data is controlled and only accessible to the department whose system stores that information, there are additional hurdles for other teams to get the crucial data they need. Decentralized systems without the tools to properly share that information from that stand-alone system to another, causes teams to share data with each other that is stale and out-of-date.

Everyone is Acting on Different Signals and Data.

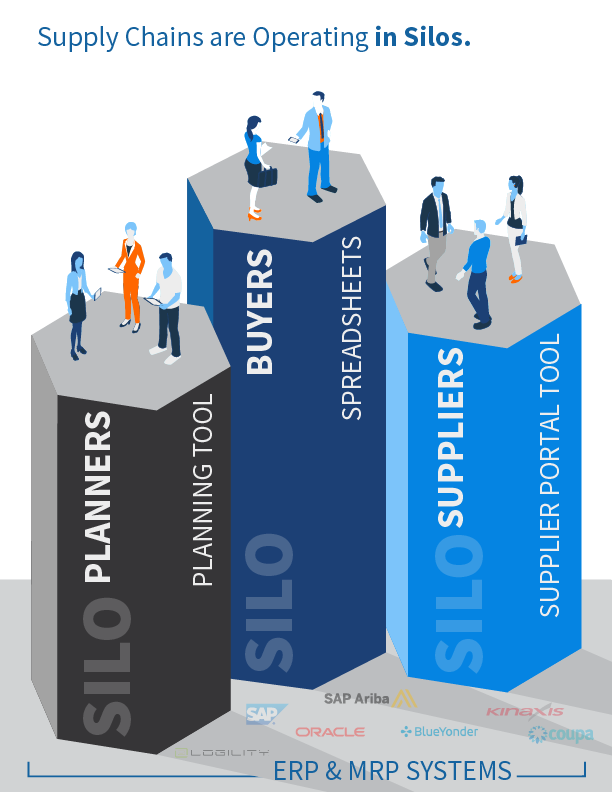

We have identified three of the main silos that isolate the different paths of the supply chain. Working from one or more enterprise planning systems, the technology doesn’t easily communicate or share information to one another. The planner is working from a siloed planning tool, the buyer is working off of the information they are sent, and the supplier is working on whatever supplier portal they are potentially provided with. All of these individual tools and information lead to miscommunications between these teams.

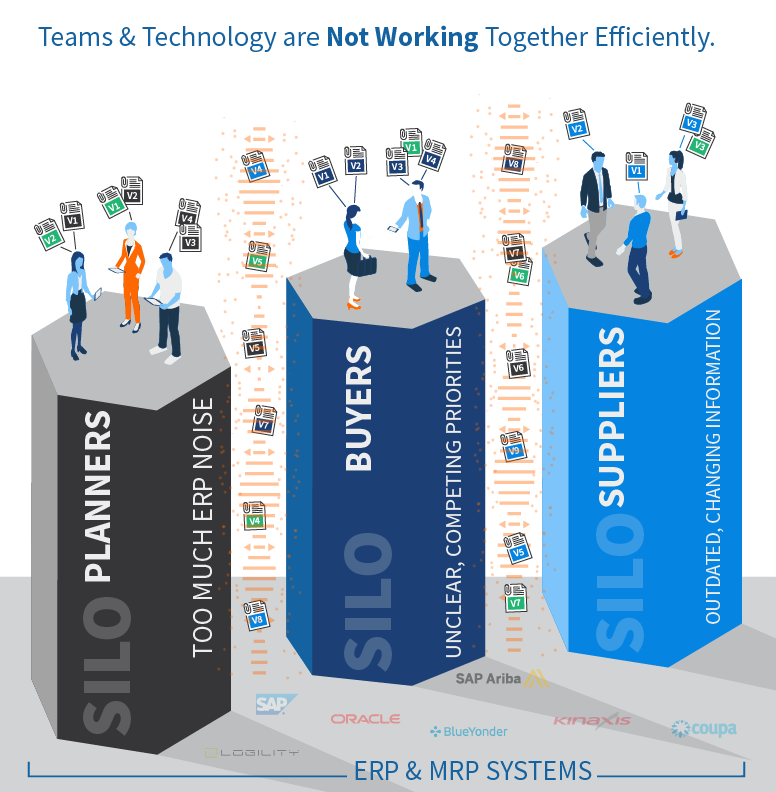

Teams in Silos Lack Prioritization and Communication

With no central prioritization tool, information overload can negatively impact your team’s performance. The image below shows how miscommunication happens between the siloed teams. No matter how many calls, emails, and or spreadsheets are shared, the information will become outdated before teams are able to get on the same page.

The Cost of Data Silos.

Poor Decision-Making

When the information you are given is out of date, the accuracy and confidence in your decision making are hindered.

Minimized Efficiency

The supply chain workforce is wasting time looking for the correct, up-to-date data when it should be easily accessible. The time that procurement teams spend searching for accurate information could be spent more efficiently towards higher valued tasks.

There is No "I" in Team

When there are collaboration bottlenecks between teams, workers tend to prioritize their own goals or objectives over the company’s overarching business needs.

And of course, all of these inefficiencies lead to huge monetary costs for the company. Siloed teams mean trouble for a supply chain that relies on connectivity.

How can organizations bridge the gap between data silos?

The key to breaking down data silos is data integration. This is most easily accomplished with a smart factory analytics solution. These solutions bridge the ERP/MRP system to the individual teams so that everyone is singing from the same sheet of music.

One of the main causes of major miscommunications between teams is the use of different tools and systems that have no connection to each other. Since the tools don’t integrate with one another, static reports have to be manually sent amongst teams, rendering them out of date as soon as they are sent.

Smart factory solutions allow manufacturers to be competitive, not only bridging the gap between teams, but unlocking more insightful data that puts organizations that one step further. These systems collect the data from the core system, the ERP/MRP, and analyze the data to provide structure and prioritization. They are also accessible by all teams, so everyone is seeing real-time updated data.

Feeling overwhelmed by information overload?

LeanDNA-List honoree Ben Galka has some advice for you. “The only way to eat an elephant is one bite at a time.” Check out his data management story.

Siloed data is rendering your analytics useless.

New analytics technologies are enabling organizations to read deeper into the story behind their data. But without supply chain collaboration, these insights are useless.

Learn more about the trouble with one-way analytics.

Let us help you optimize your inventory.

We want to help you optimize inventory by providing helpful resources that can boost productivity and drive your organization to the next level of the supply chain. Check out this critical materials report that will help you optimize your inventory.