The Secrets to Lean Six Sigma Coaching

The LeanDNA-List celebrates the hard work of our customers, who day-in and day-out work to optimize inventory, reduce shortages, and empower their companies to operate more efficiently. These winners represent the tenacious, knowledgeable, and hands-on users and champions of LeanDNA.

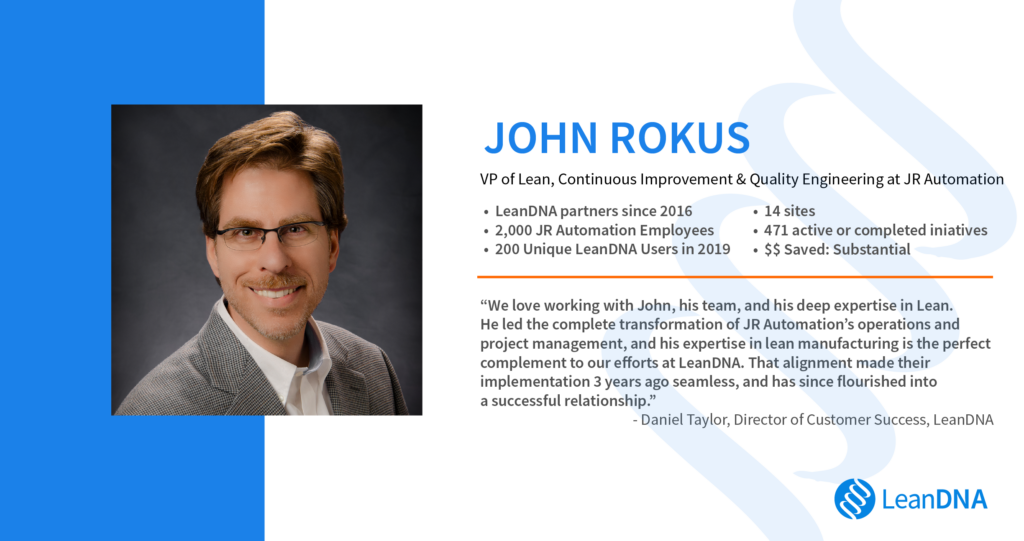

"We love working with John, his team, and his deep expertise in Lean. He led the complete transformation of JR Automation’s operations and project management, and his expertise in lean manufacturing is the perfect complement to our efforts at LeanDNA. That alignment made their implementation three years ago seamless, and has since flourished into a successful relationship.”

Daniel Taylor, Director of Customer Success, LeanDNA

Change management is a challenge across all new technology adoption, and understandably so. Any new software—no matter the ease of implementation—requires behavior changes and introduces learning curves that can hinder adoption. However, in the case of JR Automation, a LeanDNA customer since 2016, the change was led by an expert who managed the process with ease: John Rokus.

John, a black belt in Lean Six Sigma, really gets us. LeanDNA and JR Automation crossed paths when John started searching for a software platform to support his team’s Lean transformation. His experience and lessons learned from implementing Lean at several other companies set the stage for JR Automation’s future. John championed the Lean mindset, processes, and eventually our software with his team to drive waste out of the 2,000-person organization. Those efforts have earned his team the Best Achievement Award In Operational Excellence to Deliver Business Transformation at the 2019 Business Transformation & Operational Excellence Awards Summit.

The journey to a successful culture of continuous improvement and operational excellence isn’t just about the right tools; it’s also about masterfully presenting the right tools to the team who will be adopting them. John skillfully introduced LeanDNA to his team, allowing JR Automation to standardize reporting and highlight KPIs to best tell their stories and paths forward. Combining JR Automation KPIs and strategic objectives, they now have a clear line of sight into the initiatives that will have the largest impact on improving their business. John has been able to find the calm in the storm of manufacturing data and actions, and continues to iterate on Lean processes with the JR Automation team.

"LeanDNA is the best software team I've ever worked with: The most responsive, flexible, and customer-conscious. Plus, LeanDNA has a really unfair advantage. Few other software companies are built on the principles of Lean."

John Rokus, VP of Lean, Continuous Improvement & Quality Engineering, JR Automation

The feelings are mutual, John!

Know an A-lister at your company? Nominate them here!