Written by Sabari Krishnan, Head of Product, LeanDNA

Manufacturing leaders today are facing a familiar contradiction: more data than ever, but less confidence in daily execution. Volatility is persistent. Capital pressure is real. And the advice to “trust the system” or “wait until things stabilize” is increasingly disconnected from reality.

What manufacturers need now isn’t more complexity or more automation for its own sake. They need clarity and the ability to adapt continuously as conditions change. That’s why Explainable AI (XAI) is emerging as a critical foundation for modern supply chain execution. Explainable AI isn’t a new algorithm class. It’s a shift in how intelligence is delivered: transparent, interpretable, and designed for the people who must act on it every day.

Why Black-Box Planning No Longer Works

Traditional planning platforms were built for a different time with predictable demand, stable suppliers, and long planning cycles. Their core assumption was that if you optimized the model, the recommendation could be trusted.

The problem is that those systems are fundamentally opaque. They produce outputs without showing the reasoning behind them.

In today’s environment, that opacity has become a liability:

-

Operations teams must respond daily to shortages and constraints

-

Finance leaders need to understand inventory and working capital tradeoffs

-

Planners are expected to defend decisions with data, not intuition

When a system can’t explain why it’s recommending an action, teams hesitate to act—or override it entirely. Black-box logic may look sophisticated, but it breaks down when accountability and speed matter most.

As LeanDNA’s Chief Strategy Officer recently noted in Forbes: “AI creates value when it accelerates execution, not when it hides complexity behind a wall of mathematical sophistication.”

The Forecast Mirage: Why Responsiveness Matters More Than Precision

For years, supply chain strategy centered on one assumption: better forecasts create better outcomes. That assumption is eroding. As volatility increases, the marginal benefit of forecast precision declines. When demand shifts faster than planning cycles, the real differentiator isn’t accuracy, it’s responsiveness. You don’t need a slightly better map when conditions change hourly. You need real-time intelligence that helps you adjust faster than disruption unfolds. Forecast updates don’t shorten lead times. And knowing the market moved doesn’t undo a shortage already in motion. Leading manufacturers are shifting focus from forecast dependency to execution readiness (the ability to see risk early and act decisively).

What Explainable AI Enables That Traditional AI Cannot

Explainable AI delivers advanced intelligence without sacrificing transparency. Instead of issuing directives from an opaque model, XAI provides context planners and operators can trust. At its core, explainable AI enables:

-

Clarity behind recommendations - Teams can see which materials, suppliers, or constraints are driving risk.

-

Shared understanding across functions - Decisions made in planning are understandable to procurement, operations, and finance.

-

Confidence to act - In manufacturing, AI doesn’t just inform strategy, it guides daily execution. If users don’t understand the logic, adoption stalls. If something goes wrong, credibility suffers. Explainability isn’t optional; it’s what turns insight into action.

How Explainable AI Is Actually Built

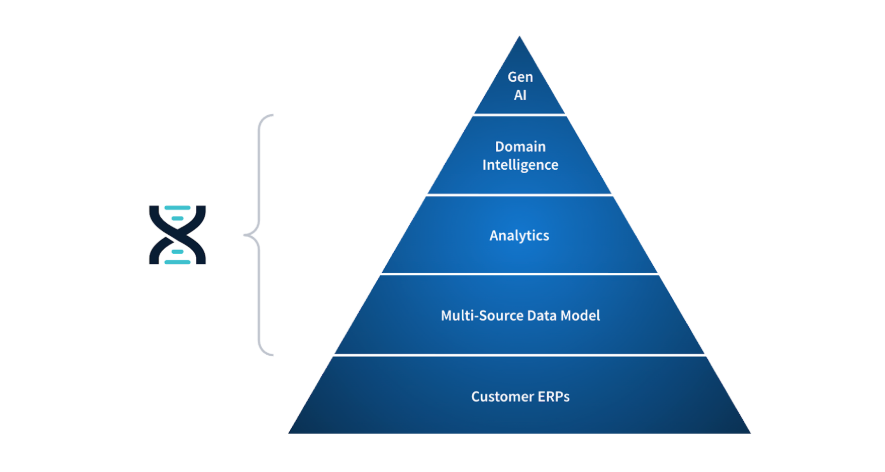

Explainable AI isn’t magic. It’s the result of a technology stack designed for execution, not abstraction. At LeanDNA, that stack looks like this:

-

Raw ERP signals from the systems manufacturers already rely on

-

A unified data model that normalizes complexity across sites and systems

-

Analytics and domain intelligence grounded in supply chain reality

-

AI and GenAI layers that surface recommendations users can understand and validate

Each layer is visible. Each assumption is grounded in domain expertise. That transparency is what enables trust. Industry research reinforces this direction. Deloitte highlights that smart manufacturing initiatives require real-time insight and decision support that frontline teams can understand. Digital transformation succeeds not by adding complexity, but by simplifying decisions and making data actionable. The pyramid below shows the progression: from raw ERP signals, to a unified data model, to analytics, to domain intelligence, and finally, GenAI that planners can trust and understand.

What Manufacturers Are Gaining with Explainable AI

Across global discrete manufacturers, explainable AI is becoming the backbone of execution strategy. The results are measurable:

-

Shortages decline because teams can see risk forming earlier

-

Inventory becomes right-sized as safety stock drivers are made explicit

-

Supplier conversations become faster and more data-driven

-

Site-to-site alignment improves as teams share the same logic and priorities

These outcomes are the direct result of replacing opaque recommendations with transparent, trusted execution guidance.

If you’d like to learn how LeanDNA’s APEX platform applies explainable AI to inventory and supply chain execution, helping manufacturers reduce shortages, improve on-time delivery, and strengthen working capital, click here to get a demo.