Written by Cameron Chen, Senior Product Manager

Procurement sits at a critical junction in the supply chain. It is where supply chain planning decisions become real commitments and where supplier performance directly affects production, delivery schedules, and working capital. Over time, we have seen that most procurement challenges are not caused by a lack of data or intent, but by the difficulty of translating insight into consistent procurement execution across the entire procurement process. Effective procurement management requires coordination among procurement professionals and procurement managers to ensure contract compliance, risk mitigation, and cost control while managing procurement workflows efficiently.

Procurement Management in APEX was built to address these gaps.

While ERP systems remain the system of record, they were not designed to support the pace, coordination, and decision-making that procurement teams face today. Buyers often work across multiple systems, manage high volumes of exceptions, and spend a significant portion of their time coordinating information that already exists but is difficult to access or act on efficiently. Even when teams understand what should change, executing those changes can be slow, fragmented, and hard to track.

This gap in efficiency highlights the need for a dedicated procurement management system that goes beyond traditional ERP capabilities. Modern procurement management software should integrate seamlessly with existing ERP platforms to streamline purchasing workflows, automate routine tasks, and provide up-to-date visibility into the entire procurement management process. Such systems enable procurement teams to manage purchase requisitions and purchase orders, negotiate lucrative production and supplier contracts, and track vendor performance more effectively.

In addition to improving internal coordination, advanced procurement management solutions enhance supplier management by fostering better communication and collaboration with external suppliers. Features like supplier portals and centralized communications reduce manual follow-ups and shorten response times, contributing to significant cost savings and improved supplier relationships.

By leveraging a comprehensive procurement management plan supported by modern procurement software, organizations can transform procurement from a business necessity into a competitive advantage that maximizes resources, controls costs, and supports sustainable business growth.

From data to procurement execution, without losing continuity

APEX by LeanDNA was created to address the supply planning and execution gap in S&OE, initially helping manufacturers make sense of their ERP data. The early focus was on transforming and harmonizing data to provide teams with a standardized view across systems like SAP, Oracle, and JD Edwards.

The platform then added recommendations to improve operational processes such as safety stock, min-max levels, and order policies.

However, while agreeing with these recommendations was straightforward, acting on them was challenging.

Executing changes required leaving APEX, navigating ERP screens, and coordinating follow-up work with suppliers via email and phone, which slowed down response times and made it difficult to link improvements directly to recommendations.

Procurement Management was developed to close this gap by connecting recommendations to execution and reflecting actions back into the ERP through a new Write-back function, enabling faster changes that stay synchronized with the system of record.

This shift transformed APEX from a tool for identifying opportunities into a platform enabling consistent, measurable procurement execution aligned with strategic business operations.

Procurement management designed around buyer workflows

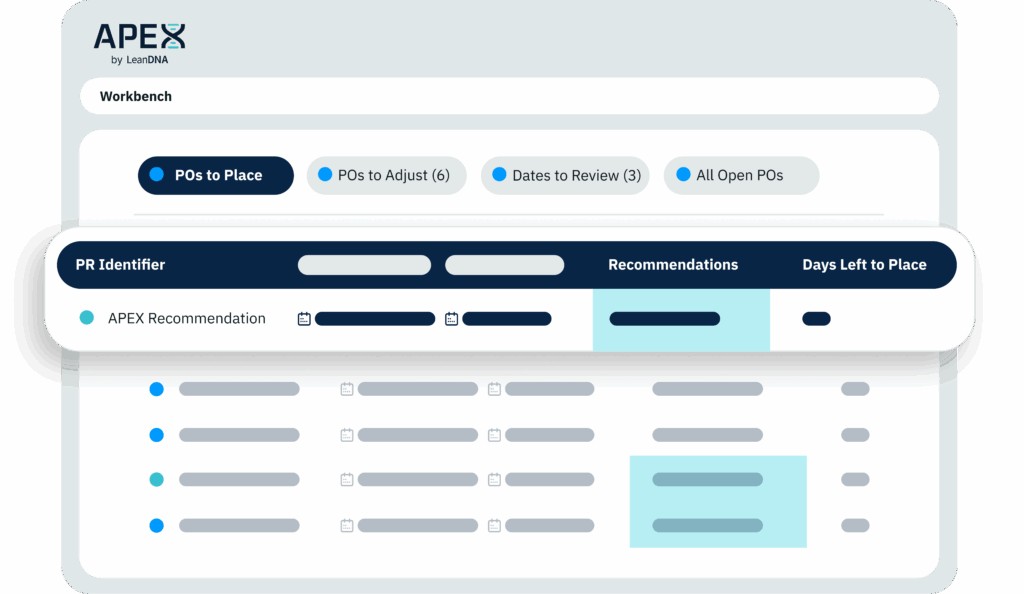

A central part of Procurement Management is Workbench, designed specifically around how procurement teams manage their day-to-day activities rather than how systems generate alerts. Traditional exception-based workflows often overwhelm purchasing agents with a high volume of notifications, offering little guidance on prioritizing tasks that truly impact business objectives. This leads to wasted time sorting through information instead of focusing on meaningful procurement execution.

Workbench refocuses efforts on prioritized actions by providing buyers with a clear view of tasks that have the greatest effect on shortages, inventory levels, or delivery performance, guided by organizational priorities and supply chain planning signals. This approach streamlines approvals and reduces time spent triaging data, ensuring procurement function efforts align with strategic business outcomes.

Over time, this consistent focus not only improves procurement decision making but also strengthens the connection between daily activities and key performance indicators, benefiting both individual contributors and project managers overseeing procurement operations.

Reducing friction in supplier collaboration and cross-functional communication

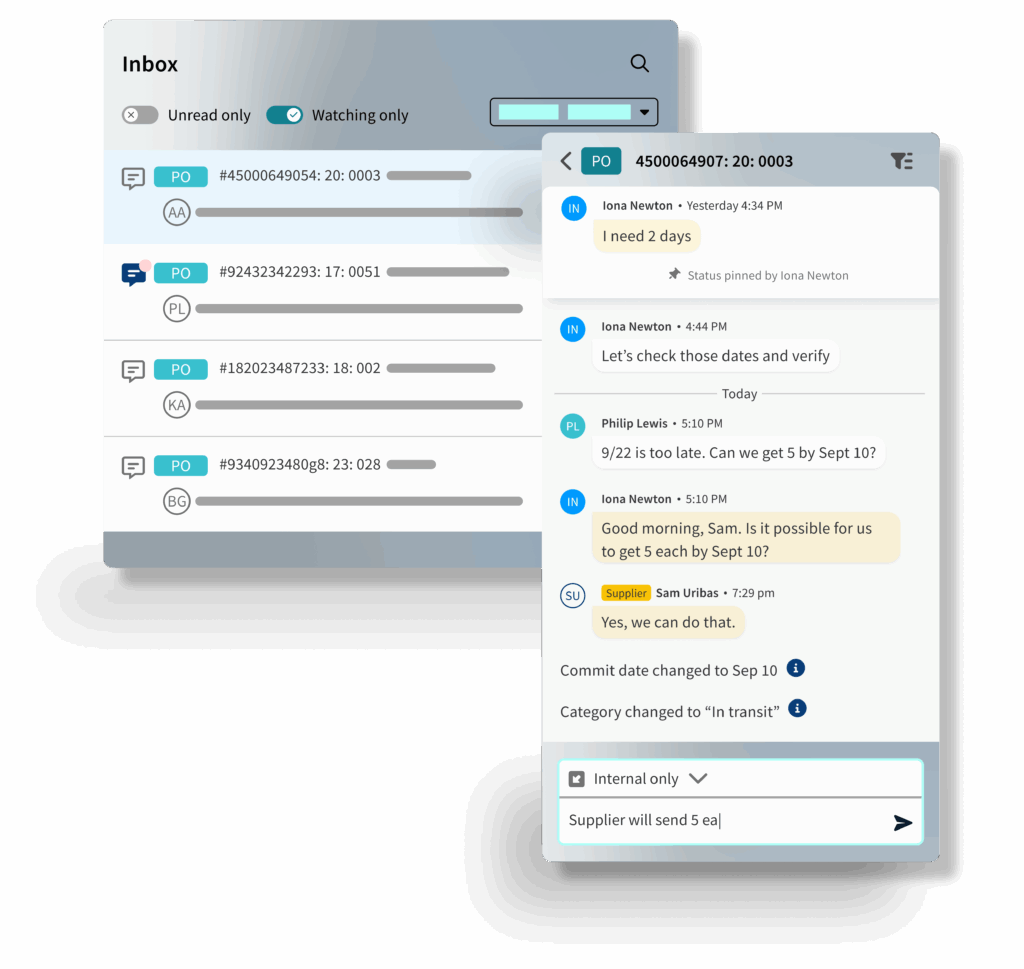

Procurement work extends well beyond transactional ordering. It requires continuous coordination with planners, suppliers, supervisors, and leadership. Historically, this coordination relied heavily on email, phone calls, and ad hoc conversations, which hinder shared visibility and increase the burden on buyers to handle repeated status requests.

Procurement Management integrates communication directly into the workflow. Features like chat, inbox, and attachments enable team members to collaborate in context, sharing the same information and history. Planners can quickly see if a buyer is already engaged with a supplier, managers can identify where issues are blocked, and suppliers can respond without relying on disconnected email threads or phone calls.

This enhanced shared visibility minimizes unnecessary interruptions, allowing procurement teams to focus more on execution rather than information relay, improving overall procurement efficiency and supplier management.

Supplier collaboration as a core part of procurement execution

Supplier Connect is often underutilized initially because teams assume onboarding will be complex or time-consuming. In reality, most value comes from focusing on suppliers representing the largest share of material risk or spend.

By simplifying supplier onboarding and making it more intuitive, Procurement Management lowers barriers to collaboration. Buyers can create supplier users directly, with onboarding communications that are self-explanatory and contextual. Information access is controlled and limited to what suppliers need to see, enabling them to self-serve demand signals and respond to requests within a single procurement system.

For buyers, this reduces inbound communication and shortens response cycles. For suppliers, it provides a clearer, more consistent engagement experience without the friction of outdated supplier portal systems, enhancing vendor relationships and supporting effective supplier management.

Write-back as a foundation for sustainable supply chain execution

Execution at scale requires that actions taken in APEX are accurately reflected in the ERP system. Without this synchronization, teams face duplicate work and risk systems drifting out of sync over time.

APEX’s Write-back functionality empowers Procurement Management to serve as a true execution layer. Buyers perform actions within Workbench, and APEX updates the ERP on their behalf. This integration reduces manual and duplicative efforts, lowers the risk of errors, and enhances data hygiene by streamlining updates within normal procurement workflows.

Over time, cleaner data supports improved analytics, enabling better procurement decision making and reinforcing trust in the procurement management system, which is essential for successful supply chain execution and strategic business operations.

Measuring impact where it matters

The value of Procurement Management manifests in multiple ways. Buyers save time by minimizing manual steps and reducing system switching. Procurement teams can proactively prevent shortages, manage inventory more strategically, and avoid costly expedites. Enhancements in supplier on-time delivery directly support customer on-time delivery, safeguarding revenue and strengthening customer relationships.

Equally important, leaders gain clearer visibility into procurement execution’s alignment with strategic priorities. Standardized work can be centrally defined and consistently reflected in daily tasks, while performance reporting monitors whether these efforts meet quality standards and drive the desired business outcomes.

A more durable model for procurement execution

Procurement Management is not intended to replace ERP systems or add another layer of complexity. Instead, it is designed to remove friction from execution and create a more reliable connection between insight, action, and outcome.

By integrating seamlessly with existing ERP platforms, procurement management software streamlines purchasing workflows, reduces manual tasks, and enhances real-time visibility across the entire procurement process. This integration empowers procurement teams to prioritize effectively, collaborate with suppliers, and respond swiftly to changes in consumer demand or supply chain disruptions.

When procurement teams have clear priorities, shared visibility, and the ability to act without unnecessary overhead, execution becomes more consistent and sustainable. Over time, that consistency enables procurement to contribute not only to operational efficiency but also to measurable improvements in strategic business performance and supply chain execution.

For more information about APEX Procurement Management, get in touch with us here and one of our experts will reach out to you.